Blow Bars For Mesto LT1110 Crusher Wear Parts

Crusher Wear Blow Bars Introduction

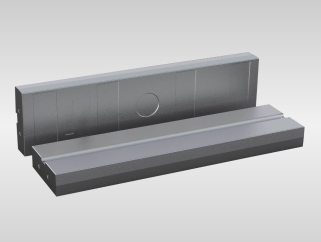

Blow bars are thick slabs of metal, typically made of a chrome mixture, designed for breaking apart materials like asphalt, concrete, and limestone. They play a critical role in the crushing process of a horizontal shaft impactor. The materials used for blow bars are selected based on the function of the impact crusher. When inserted into the rotor of horizontal impact crushers, the blow bars rotate at high speeds, repeatedly striking the material. This continuous action fractures the material until it reaches the appropriate size to pass through the impact crusher chamber.

Crusher Wear Blow Bars Parameters

| Material Code |

Description | Wear Life | Feed size | Tramp Iron | Typical Applications |

| 200S | Manganese | Short | No limitation | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 200ST | Manganese + TiC insert | 2x times 200S | No limitation | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 550M | Low chrome (Martensitic) | Medium | < 800 mm | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 550MC | Low chrome (Martensitic) w/ceramic |

2x times 550M | < 800 mm | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 550MCT | Reinforced Low chrome ceramic |

1.5x times 550MC | < 800 mm | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 550MYT | Reinforced Low chrome NewGen ceramic |

2x times 550MC | < 800 mm | Allowed | Concrete, asphalt slabs recycling, Natural stones etc |

| 600C | Medium chrome | Long | < 400 mm | Not allowed | Concrete recycling, Natural stones etc |

| 600CC | Medium chrome ceramic | 2x times 600C | < 400 mm | Not allowed | Concrete recycling, Natural stones etc |

| 600CCT | Reinforced Medium chrome ceramic |

1.5x times 600CC | < 400 mm | Not allowed | Concrete recycling, Natural stones etc |

| 650C | High chrome | Long | < 200 mm | Not allowed | Concrete recycling, Hard natural stones etc |

| 650CC | High chrome ceramic | 2x times 650C | < 200 mm | Not allowed | Concrete recycling, Hard natural stones etc |

| 700CCT | Reinforced High chrome |

1.5x times 650CC | < 200 mm | Not allowed | Concrete recycling, Hard natural stones etc |

| 700CX | Reinforced High chrome ceramic |

2x times 650CC | < 200 mm | Not allowed | Hard natural stones, Granites, Quartzes etc |

M200 (Manganese Steel): Suitable for large feed size, low-abrasive stones (e.g., limestones), with input size ≥800mm. It can contain scrap iron.

M200TIC (Manganese Steel + TIC): Similar to M200 but designed for applications where a longer wear life is required.

550M (Martensitic Steel): Suitable for medium feed size, low to medium abrasive materials like limestones, asphalt, concrete, and building rubble with steel rebars or a small amount of unbreakable objects.

MC Series (Martensitic Steel + Ceramic):Used for materials with no iron content, input size >300mm. Ideal for primary crushing and recycling of building rubble with low to medium iron content, concrete, and natural stones.

MC+ Series (Martensitic Steel + Ceramic): Similar to MC series but designed for applications requiring a longer wear life.

MY Series (Martensitic Steel + Ceramic – New Generation): Similar to MC+ series but designed for applications requiring an even longer wear life.

650C (High Chrome Steel): Suitable for small feed size, medium to high abrasive but low-strength materials like limestones, asphalt, concrete, and building rubble without steel rebars or unbreakable objects.

CC Series (High Chrome + Ceramic): Similar to 650C but designed for applications where a longer wear life is required.

CC+ Series (High Chrome + Ceramic – New Generation): Suitable for small feed size, high abrasive, and high-strength materials like gravels and granites, without unbreakable objects.

Why Choose SAIKUANG Crusher Wear Blow Bars

1.

2.

3.

4.

5.

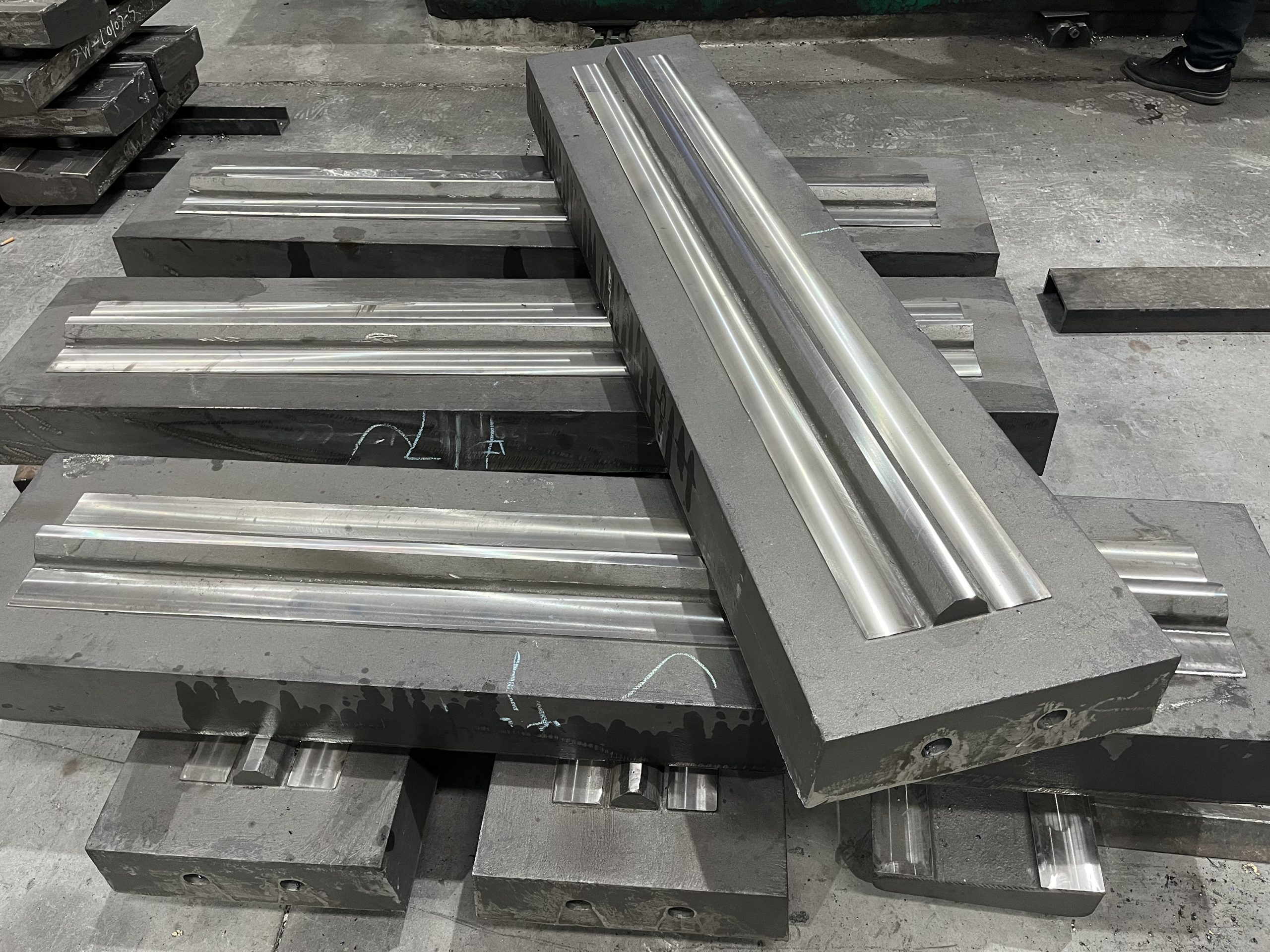

Crusher Wear Blow Bars Details

FAQ

Here are the FAQs.

-

Q

What kind of material are you familiar with?

Awe focus on chrome with ceramic ,martenstic with ceramic crusher wear parts. -

Q

What is your advantage in your industry?

AWe have a large number of molds for different brand, and wearing life can be double and more than normal material. -

Q

If can do according to OEM drawing?

AYes, we had customers from over 40 countries, thousands of mold parts are customed.

Why Choose Us

Strictly control the quality of each batch of raw materials, pre-sales and after-sales

customer site visits.

-

.webp)

Quality Inspection

Our engineer will trace the

production records according to the casting number, and analyzing the casting sample again

we kept, the pictures will bring a lot of information what we need.

Our engineer will trace the

production records according to the casting number, and analyzing the casting sample again

we kept, the pictures will bring a lot of information what we need. -

.webp)

Quality Inspection

Chemical Analysis Report

Chemical Analysis Report CColoring Flaw Detection Inspection

CColoring Flaw Detection Inspection

Dimension Accuracy Inspection

Dimension Accuracy Inspection Magnetic Particle Inspection

Magnetic Particle Inspection -

.webp)

Customer Service

Customer site visits, both before &

after sales

Customer site visits, both before &

after sales Technical proposal in response to

the customer

specific requirements

Technical proposal in response to

the customer

specific requirements -

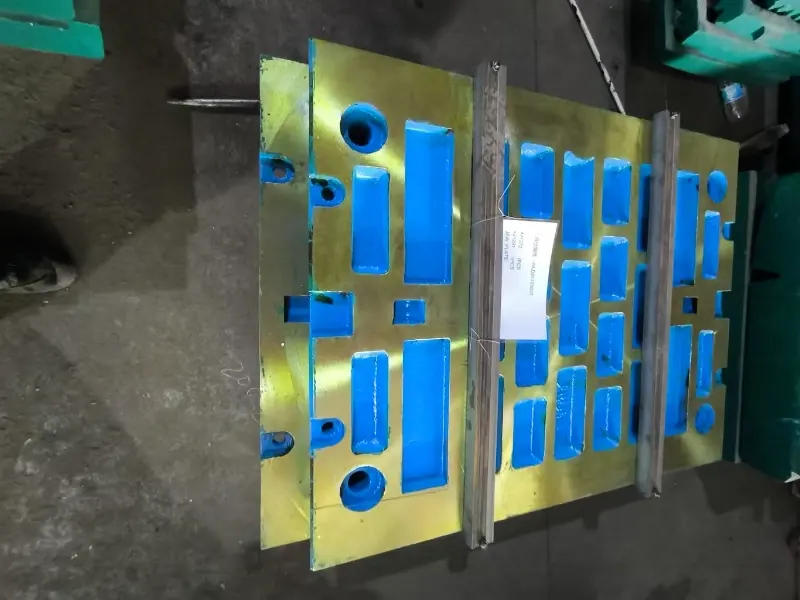

.webp)

Guarantee Delivery

There are thousands of wear parts

patterns can be used, which can short your delivery time.

There are thousands of wear parts

patterns can be used, which can short your delivery time. Process in the highest priority to

meet clients short and urgent delivery request.

Process in the highest priority to

meet clients short and urgent delivery request.